-

Products

-

Lab Instruments

Titration Systems Other Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

EZ Series Analysers

- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

- Flow and Collections

-

Online Sensors and Controllers

Conductivity Sensors

- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 9523 Cation Conductivity

- Multiparameter Online Panels

- Claros Water Intelligence System

- Test Kits & Strips

-

Microbiology

Prepared Media

- BARTS

- Liquid MPN

- MUG Tube

- Membrane Filtration

- Paddle Testers

- Presence-Absence

- Total Count Media

- Yeast and Mold

Labware- Accessories

- Funnels, Pumps & Manifolds

- Microbiology Filters

- Petri Dishes & Accessories

- Sampling Bags

- Vials, Tubes, Bottles & Racks

-

Lab Equipment and Supply

ApparatusInstruments Glassware/PlasticwareGeneral Lab Consumables Safety Equipment Books and Reference Material

- Samplers

- Industrial UV

- Electrochemistry

-

Lab Instruments

- Parameters

- Industries

- Support

- Service

- e-Shop

- Brands

Hach Australia

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

- Vietnam

Middle East - Africa

Prices Online Include GST 1300 887 735

Municipal Wastewater Treatment

Do More with Less

Reduce Wastewater Costs with Hach Wastewater Treatment Solutions

Australia’s municipalities face increasing pressure to improve water quality, meet strict environmental compliance, and operate within tight budgets.

Each wastewater treatment plant is unique in its own capacity, processes, and effluent limits. Every wastewater plant is also faced with rising chemical costs and regulations.

Hach delivers smart wastewater treatment solutions for evolving infrastructure needs for all water treatment stages.

Explore Elechtrochemistry Meters

For the Ones Who Keep Water Safe.

This Is for You

You're not just running a plant. You're safeguarding communities, rivers, and oceans. Every sample you test, every valve you adjust, and every reading you log plays a part in Australia’s water future. Hach water quality equipment helps you protect our most precious resource.

Hach Featured Solutions Are Designed Around You

Hate taking grab samples during storms? Our sensors stay online and accurate — rain or shine.

Learn More

You're not just running a plant. You're safeguarding communities, rivers, and oceans. Every sample you test, every valve you adjust, and every reading you log plays a part in Australia’s water future. At Hach, we don’t just build instruments, we build tools that help you protect our most precious resource.

And when it comes to service, we’ve got your back. Our factory-trained technicians provide expert installation, maintenance, and repair - minimising downtime and ensuring compliance.

We Understand Your Challenges

| Treatment Step | Challenge | Product Solution |

|---|---|---|

| Aeration | High energy use | LDO 2 sc – Save up to 30% energy |

| Nutrient Removal | Discharge limits | NT3100sc – Accurate nitrate control |

| Sludge Handling | Overdosing risk | Solitax – Suspended solids optimization |

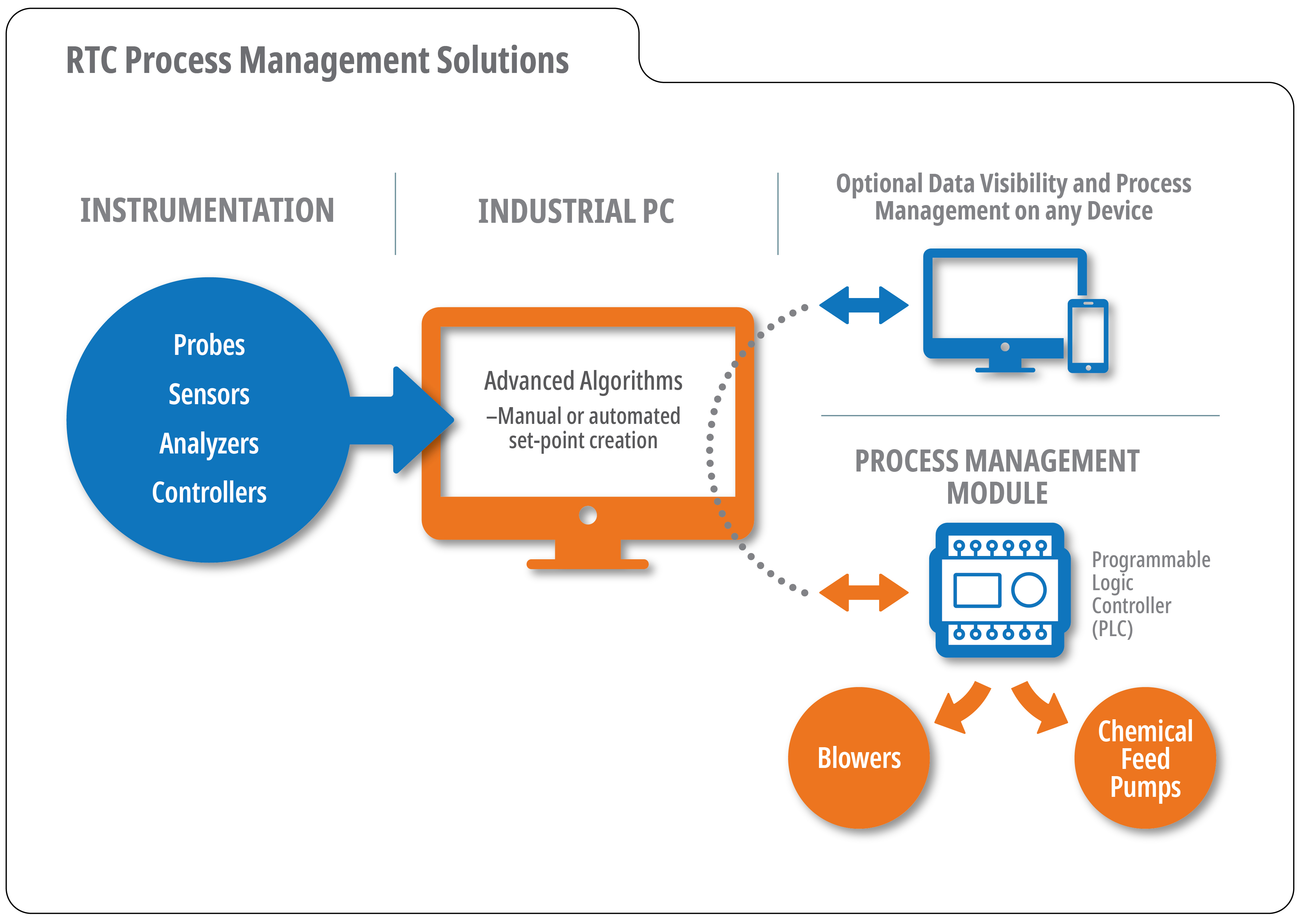

| Automation | Manual adjustments | RTC – Real-time control with alerts |

Optimize Every Stage of Wastewater Treatment:

Click on the process flow dots to learn more.

Collection Systems

Modern sanitary sewer collections systems move wastewater through a series of pipes from residential buildings, businesses, and industrial sites to wastewater treatment facilities for processing and discharge. Some older systems know as combined sewer systems also carry stormwater runoff in addition to the wastewater from residential and commercial sources.

The wastewater flows through underground sewer mains, most often by gravity, but sometimes assisted by pumps situated at lift stations. Depending on the topography of an area, these force mains vary in length up to a few miles long. Interceptors are locations where two lines meet and flow into a larger pipe, and can include large chambers accessible by manholes.

Flow Monitoring

Does your collection system experience excess flow during dry and wet weather? Have you confidently pin-pointed the source?

Do you ever experience sewer overflows?

Are you confident your collection system can handle additional flows from residential and commercial expansion?

Do you need to spot check or verify flow rates using a handheld instrument?

Hach offers solutions to your open channel flow monitoring needs.

Preliminary and Primary Treatment

Preliminary treatment is typically the first process within the treatment

During primary treatment, primary clarifiers allow organic solids to settle through gravity, while fats, oils

Process Step

Plant Inlet (Raw Influent)

Do you consistently monitor the relevant parameters in your influent to adjust your plant’s processes accordingly?

Do you have good transparency on the changes at your influent?

Hach offers solutions to your Primary Treatment needs. Explore the following solutions:

Parameters

Ammonia

Process: EZ3501 Ammonia Analyzer, EZ4005 Ammonia Analyzer

Conductivity

Lab: HQ40D Portable Meter with CDC401 sensor

Dissolved Solids

Process: 3700 Inductive Sensors

Lab: HDQ Portable Meters

TOC, TP, TNProcess: BioTector B7000i Analyzer, UVAS plus sc Sensor

Lab: n/a

pH

Process: Digital Differential pH Sensors, Combination pH Sensors

Lab: HQ30D pH Meter with PCH101 Sensor

Suspended Solids

Process: TSS sc Sensors, Solitax sc Sensors,

Lab: TSS Portable, Gravimetric Test

Toxicity

Process: EZ1000 Toxicity Analyzers,

Lab: n/a

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Sand Trap / Grit Chamber

Can you protect your treatment plant from industrial dischargers and monitor shock loads?

Hach offers solutions to challenges in your Sand Trap / Grit Chamber. Explore the following solutions:

Process Controllers

Claros Mobile Sensor Management enabled device

Influent to Primary Clarifier

Do you have clarity on your N, P and C levels for the next treatment steps?

Hach offers solutions to challenges in your influent to your Primary Clarifier. Explore the following solutions:

Parameters

COD

Process: EZ7000 Series COD Analyzers,

Lab: n/a

Dissolved Solids

Process: 3700 sc Sensors

Lab: HQd pH Meter with CDC401 Sensor

Multiple (TOC, P TP, TN, TKN, COD)

Process: BioTector B7000iTOC Analyzer , UVAS plus sc Sensor

Lab: n/a

Orthophosphate

Process: Phosphax sc Phosphate Analyzer

Lab: n/a

pH

Process: pHD Sensors, Combination pH Sensors

Lab: HQD pH Meter with PCH101 Sensor

Suspended Solids

Process: TSS sc Sensors, Solitax sc Sensors,

Lab: TSS Portable, Gravimetric Test

Process Controllers

Claros Mobile Sensor Management enabled device

Primary Clarifier

Do you optimize your sludge Draw-Off (Sludge Removal) to your Biodigestor?

Can you accurately monitor your sludge levels?

Hach offers solutions to challenges in your Primary Clarifier. Explore the following solutions:

Process Controllers

Claros Mobile Sensor Management enabled device

Primary Treatment Effluent

Is your primary clarification operating adequately?

Are you providing optimal levels of N, P, and C for your secondary clarifier?

Are your pH and Alkalinity levels appropriate, not to damage the bacteria in your secondary treatment?

Hach offers solutions to challenges in your Primary Treatment Effluent. Explore the following solutions:

Parameters

Alkalinity

Process: EZ4000 Series Analyzers,

Lab: AT10000 Alkalinity Instrument

Ammonium

Process: Amtax sc Analyzer, A-ISE sc Sensors, AN-ISE sc Sensors

Lab: n/a

BOD

Process: n/a

Lab: HQD pH Meter with LBOD Sensor,

COD

Process: EZ7000 Series Analyzers,

Lab: n/a

Conductivity

Process: n/a

Lab: HQD pH Meter with CDC401 Sensor

pH

Process: phD sc Sensors, Combination ph Sensors

Lab: HQD pH Meter with PCH101 Sensor

SAC

Process: UVAS Plus sc Sensor,

Lab: n/a

Suspended Solids

Process: TSS sc Sensors, Solitax sc Sensors,

Lab: TSS Portable, Gravimetric Test

Multiple (TOC, P, TP, TN, TKN, COD, Metals)

Process: BioTector B7000i Analyzer

Lab: n/a

Orthophosphate

Process: Phosphax sc Phosphate Analyzer

Lab: n/a

Oxygen Uptake Rate

Process: n/a

Lab: HQD Dissolved Oxygen Meter with LD sensor

Toxicity

Process: EZ7900 Analyzer

Lab: n/a

Volatile Acids

Process: EZ7200 Analyzer

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Secondary treatment

Secondary treatment removes the soluble organic matter, nutrients such as nitrogen and phosphorus, and most of the suspended solids that escape primary treatment. Most often, biological processes are used in which microbes metabolize organic compounds and nutrients to grow and reproduce. The two most common biological secondary treatment processes are

For biological treatment to function efficiently, organisms require nutrients in a balanced ratio, including carbon, nitrogen, and phosphorus (referenced as C:N:P), as well as trace elements including iron, copper, zinc, nickel, manganese, potassium, sulfur, and other components which are typically present in wastewater. The commonly accepted C:N:P Ratio is 100:5:1, although some facilities thrive outside of this ratio, while others experience polysaccharide slime formation or filamentous bacteria growth that inhibit the biology and settling in the secondary clarifier.

Multiple biological processes can be employed to complete secondary treatment, including plug flow aeration basins, complete mix aeration tanks, sequencing batch reactors, oxidation ditches, trickling filters, moving bed biological reactors, integrated

Biological Nutrient Removal (BNR) alters the environment of the microorganisms to remove nitrogen and phosphorus from the water. A BNR process consists of anaerobic (no oxygen or nitrate), anoxic (no oxygen, nitrate is present), and aerobic (oxygen present) stages, during which the water is moved through a series of chambers to perform various biological functions.

Chemical treatment processes can also be used, such as the chemical removal of phosphorus. By introducing a chemical precipitant to within the aeration basin and clarifiers, phosphorus is removed by flocculation, binding into insoluble compounds that settle out and can be removed as sludge.

Application Specific Solutions

Nitrogen Removal:

Whether you are facing new regulations or trying to become more efficient, we can provide solutions for monitoring nitrate, dissolved oxygen, and other parameters that can save energy and chemical costs while optimizing nitrification and denitrification in your facility.

Learn more with Hach’s Nitrogen Removal Guide.Phosphorus Removal:

Whether you need a solution for chemical or energy savings, we can provide monitoring solutions that can save costs while optimizing your Phosphorus removal.

Learn more with Hach’s Phosphorus Removal Guide.Aeration Control:

If you are interested in lowering energy and maintenance costs, we have products with innovative luminescent technology to monitor dissolved oxygen and optimize your aeration control.

Learn more with Hach’s Aeration Control Guide.Dissolved Air Flotation (DAF) Optimization:

Does your facility

Process Step

Nitrogen Removal

Is your process for Carbon and Nitrogen removal optimized?

Do you control your Dissolved Oxygen levels manually, using a fixed set point, or based solely on flow rates?

Do you face significant electricity costs due to manual or fixed aeration controls?

Several technologies are used for Biological Nitrogen removal in wastewater treatment plants. From continuously-aerated treatment systems, to intermittent operated plants, sequencing batch reactors, and more, nitrogen elimination is often the central process in the wastewater treatment plants. While variations exist, this process usually requires real-time measurement of ammonium and nitrate for adjustment of DO concentration and optimization of nitrification and denitrification times. Hach offers solutions for your nitrogen removal needs. Explore the following solutions:

Parameters

Alkalinity

Process: EZ4000 Series Analyzers,

Lab AT1000 Alkalinity Intrusment

Ammonium

Process: Amtax sc Analyzer, A-ISE sc Sensors, AN-ISE sc Sensors

COD

Process: EZ7000 Series Analyzers

Lab: n/a

Dissolved Oxygen

Process: LD02 sc Sensors

Nitrate

Process: EZ1000 Series Analyzers

Lab: n/a

Nitrite

Process: EZ1000 Series Analyzers

Lab: n/a

pH

Process: phD sc Sensors, Combination ph Sensors

Sludge Volume and Sludge Volume Index

Process: n/a

Lab: Settlometer

Suspended Solids

Process: TSS sc Sensors, Solitax sc Sensors,

Lab: TSS Portable, Gravimetric Test

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Phosphorus Removal

Is your Phosphorous removal process optimized?

Do you control the chemical dosing manually, using a fixed dosing amount or based solely on flow rates?

Do you face significant chemical costs due to manual or fixed dosing of chemicals?

Chemical phosphorus removal is a critical step in wastewater treatment. It is usually done by adjusting chemical dosing of precipitants, based on phosphate concentration and flow, allowing for consistent effluent phosphorus values. Hach offers solutions for your Phosphorous removal needs. Our solutions range from complete optimization & control of the Phosphorous removal process with Claros Process Management to instruments that cater to the specific parameters you need.

Parameters

Orthophosphate

Process: Phosphax sc

Sludge Volume and Sludge Volume Index

Process: n/a

Lab: Settlometer Kit

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Secondary Clarifier

Do you optimize your sludge Draw-Off (Sludge Removal) to your Biodigestor?

Hach offers solutions for your clarification needs. Explore the following solutions:

Process Controllers

Claros Mobile Sensor Management enabled device

Tertiary Treatment

In tertiary treatment, techniques such as filtration, disinfection, carbon absorption, and other processes are used to remove the remaining organic load, suspended or dissolved solids, pathogens

Process Step

Disinfection

Is your disinfection process working optimally?

Hach offers solutions to your disinfection needs. Explore the following solutions:

Parameters

UV Transmittance

Process: UVAS sc Sensor

Lab

Total Chlorine

Process: CL17

Lab

Monochloramine

Process: 5500sc Ammonia Monochloramine Analyzer

Lab:

Process Controllers

Claros Mobile Sensor Management enabled device

Filtration

Are your filters working at maximum efficiency?

Hach offers solutions for your clarification needs. Explore the following solutions:

Parameters

Turbidity

Process: TU5300/TU5400sc Laser Turbidimeters, Solitax sc Sensors

Lab: TL2300 Turbidimeter

Process Controllers

Claros Mobile Sensor Management enabled device

Solids Handling

The method for handling the sludge removed from the process depends on the volume of solids as well as other site-specific conditions. Aerobic digestion is often used by facilities less than eight million gallons per day of inflow. Waste Activated Sludge and if present, Primary Sludge, are added to an aerated reactor where microorganisms feast on the organics and microorganisms present in the sludge to reduce the volatile solids content and the overall mass of sludge. Anaerobic digestion is typically used at facilities greater than eight million gallons per day of

Thickening involves concentrating the sludge by removing a percentage of the liquid portion by adding polymer

Applications

Sludge Thickening

Is your sludge thickened to an optimal level right now? How do you know?

How are you optimizing your sludge thickening system and chemical use?

How are you monitoring the impact of your thickener side stream?

Sludge thickening is a critical step for most biosolids management plans. It is the first step for reducing the sludge volume by removing free water. Sub-optimal sludge thickening has a large economic impact on the disposal costs. Solids carryover from centrate or filtrate can cause unnecessary pressure when returning the side stream to the beginning of the plant. Let us help you find the best solution for improving your visibility into your sludge thickening process.

Products

Total Suspended Solids

Process: Solitax sc Sensors

Portable: TSS Portable

Methods.Procedures: Gravimetric Testing

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Biosolids Dewatering

Is your sludge dewatered to an optimal level right now? How do you know?

How are you optimizing your sludge dewatering system and chemical use?

How are you monitoring the impact of your dewatering side stream?

Sludge dewatering is a critical step for most biosolids management plans. It is typically the final step in water/solids separation for the reduction in sludge volume before disposal or drying. Sub-optimal sludge dewatering has a large economic impact on the disposal costs. Solids carryover from centrate or filtrate can cause unnecessary pressure when returning the side stream to the beginning of the plant. Let us help you find the best solution for improving your visibility into your sludge dewatering process.

Products

Total Suspended Solids

Process: Solitax sc Sensors

Portable: TSS Portable

Methods.Procedures: Gravimetric Testing

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Sludge Digestion

Are your digesters operating at maximum efficiency?

How often do you monitor conditions of your digesters to ensure optimal performance?

Water resource recovery systems face the challenge of managing the biosolids generated as a part of the water recovery process. Digesters, both aerobic and anaerobic, are used to reduce the mass of biosolids and, in many cases, used to recover additional natural resources, such as biogas and nutrients. Whatever your specific needs are, let us help you find the best technology available.

Products

Alkalinity

Process: EZ Series Analyzers

Lab: AT1000 Titrator Instrument

pH

Process: pH Sensors

Lab: HQD Portable Meter with PHC101 Electrode

Volatile Fatty Acids

Process: EX Series Analyzers

Lab: n/a

Dissolved Oxygen

Process: LDO2sc DO Probe

Lab: HQd Meter with LDO sensor

Ammonium

Process: Amtax sc Ammonium Analyzer

Process: A-ISE sc Ammonium Sensor

Lab: n/a

Nitrate

Process: Nitratax sc UV Sensor

Process: N-ISE sc ISE Nitrate Sensors

Process: AN-ISE sc Sensors

Lab: n/a

Hardness

Process: : EZ Series Analyzers

Process Controllers

Samplers

Claros Mobile Sensor Management enabled device

Water Intelligence

A growing field of expertise within the wastewater treatment industry, Water Intelligence Systems use digital technologies, advanced sensors, controllers, and algorithms to allow plant operators to increase efficiencies leading to overall cost savings in running the plant.

Claros TM, the Water Intelligence System from Hach, integrates all plant data sources, including system data, device data, and manually-collected data, driving decisions to maximize efficiency and cost savings.

With these systems, data on flow rate, water composition, dissolved-oxygen, nutrient levels, and other factors are more easily tracked and verified. This leads to more responsive treatment options, automation capabilities, and data visualization and report generation.

Using data-driven insights into water quality, flow rate, and other factors, operators can reduce overtreatment (chemicals as well as aeration blower run time) while knowing their plant will remain within compliance limits.

As regulations become more stringent and plants need to find cost-savings, Water Intelligence Systems such as Claros will become more important and widely adopted. And with the Hach’s growing suite of Claros-Enabled sensors, controllers, devices, Process Management systems, and lab equipment, operators can configure a system that fits the unique requirements of any plant.

Interested in learning more? Visit hach.com/claros

Regulations

Regulations and permit limits vary from region to region and country to country. Generally, target limits are established by the acting authority, and plants measure and report to demonstrate compliance with established limits. In this way, important parameters that indicate water quality and environmental and health standards are monitored and maintained, ensuring the continued health and safety of the populations being served.

For information regarding regulations in the US: https://www.epa.gov/npdes

For information regarding regulations in the EU: https://www.eea.europa.eu/themes/water/water-management

For information regarding regulations in

Effluent & Reuse

While effluent from wastewater treatment facilities is commonly discharged to the environment in rivers, oceans, or other bodies of water, there are a variety of other options for discharge. These include agricultural irrigation; use in parks and recreational facilities (golf courses and sports field irrigation,

Applications

Flow Monitoring

How are you monitoring your effluent flow?

Are you confident in the measurements?

Do you need to verify your effluent flow with a handheld instrument?

Hach offers solutions to your open channel flow monitoring needs. Explore our solutions

Phosphorus

Do you wish you had a better handle on your phosphorus removal?

How do you monitor the phosphorus in your effluent? Do you trust the results?

The demand to meet effluent phosphorus requirements is growing for water resource recovery and reuse facilities. Continuous online analyzers or EPA equivalent laboratory tests help ensure you have maximum visibility of your system performance and will help prevent costly or embarrassing upsets and violations. Here you can find many flexible solutions that span the range for quick spot testing to continuous online monitoring to EPA approved methods for both orthophosphate and total phosphorus.

Products

Claros Mobile Sensor Management enabled device

Nitrogen

Are you confident you are meeting your effluent nutrient targets right now?

Are you facing a challenging Ammonia or Total Nitrogen regulation?

The demand to meet effluent Total Nitrogen, Ammonia, and/or nitrate requirements is growing for water resource recovery and reuse facilities. Continuous online analyzers or EPA equivalent laboratory tests help ensure you have maximum visibility of your system performance and will help prevent costly or embarrassing upsets and violations. Here you can find robust laboratory and real-time monitoring solutions for nitrogen in all its relevant forms.

Products

Spectrophotometers

Nitrate Sensors

Ammonium Analyzers

Total Nitrogen Analyzers

US EPA Compliant Lab Methods

Ammonium as Nitrogen

Ultra-Low Range

Low Range

High Range

Ultra-High Range

Nitrate as Nitrogen

Nitrite as Nitrogen

Total Nitrogen

Claros Mobile Sensor Management enabled device

Organics (BOD, TOC, COD)

Are you confident you are meeting your effluent BOD permit right now?

All water resource recovery facilities are required to reduce the number of organics in their effluent. Whether the goal is regulatory compliance reporting or real-time monitoring of a particularly critical treatment process, we have flexible solutions worth exploring.

Products

Lab/Portable Meters

Spectrophotometers

TOC Analyzers

BioTector B7000i Analyzer

EZ Series Analyzers

Organics Load

Claros Mobile Sensor Management enabled device

Solids/Turbidity

Are you confident you are meeting your effluent turbidity or solids targets right now?

Does your reuse application require accurate and consistent turbidity monitoring?

All water resource recovery facilities are required to reduce the amount of total suspended solids in their effluent. Many facilities also doing beneficial reuse of their effluent stream are also required to monitor turbidity. Whether the goal is regulatory compliance reporting or real-time monitoring of a particularly critical treatment process, we have flexible solutions worth exploring.

Products

US EPA Compliant Lab Methods

Solids

Dissolved Solids

Filterable Solids

Settleable Solids

Total Solids

Total, Non-Filerable Solids

Volatile, Non-Filerable Solids

Turbidity

Method 8195

Mitchell Turbidity Method

Claros Mobile Sensor Management enabled device

Oil and Grease

Has your process removed enough oil and grease to comply with regulations or downstream reuse requirements?

Water resource recovery facilities face the challenge of reducing fats, oils, and greases prior to discharge or sensitive downstream reuse applications. Whether you are looking for quick laboratory methods or online monitoring solutions to help gain visibility to a critical process, let us help you find the best solution.

Products

UV Flourescence Probe

Claros Mobile Sensor Management enabled device

pH

Are you confident you are meeting your effluent pH target right now?

How do you monitor your effluent pH? Are you confident in the measurement?

Accurate effluent pH is required to protect the downstream needs, whether it is discharging into the environment or being captured for beneficial reuse. Ensuring the best data is being used for your needs requires the best equipment. Let us help you find the best solution for your pH measurement needs.

Products

US EPA Compliant Lab Methods

Claros Mobile Sensor Management enabled device

Dissolved Oxygen

Are you confident you are meeting your effluent Dissolved Oxygen target right now?

How do you monitor your effluent Dissolved Oxygen? Are you confident in the measurement?

Accurate effluent Dissolved Oxygen is required to protect the downstream needs, whether it is discharging into the environment or being captured for beneficial reuse. Ensuring the best data is being used for your needs requires the best equipment. Let us help you find the best solution for your DO measurement needs.

Products

Claros Mobile Sensor Management enabled device

Disinfection

Are you confident you are meeting your effluent disinfection requirements right now?

Does your reuse application require consistent disinfection? How do you ensure compliance?

Water resource recovery facilities often face disinfection requirements for their effluent and reuse streams. Whether your site is using UV irradiation, Chlorine oxidation (in any form), or something else, Hach has a flexible suite of laboratory and online monitoring solutions. Let us help you find the best solution for your disinfection goals.

Products

Spectrophotometers

Automatic Titrators

Online Chlorine Analyzers

LC10sc Chlorine Analyzer

CL10 sc Amperometric Chlorine Analyzer

Digital UV Probes

Claros Mobile Sensor Management enabled device

Microbiology

Does your effluent contain the right microbiology?

Effluent microbial counts are key parameters that help ensure water discharging from Water resource recovery facilities is safe for our environment and ourselves. Let us help you find the best solution for your specific goals.

Products

Microbiological Testing

Samplers

Claros Mobile Sensor Management enabled device

Recurring Orders

Recurring Orders